Engicam has partnered with Micron and Silica to deliver complete components and support solutions.

Engicam, a company based in Italy, has a long history of providing design services for high-tech electrical systems.

By building strong relationships with customers, Engicam has created successful collaborations with major national companies in the consumer, automotive, marine, and rail industries, as well as small and medium firms operating in industrial market categories.

In 2009, Engicam began offering a variety of CPU modules (system-on-a-module, or SOM) based on the latest-generation ARM processors to help developers create more innovative and technologically advanced products. By investing in these devices, Engicam can continue to develop increasingly powerful and efficient platforms. Engicam’s philosophy is to support clients at every step of the development process and integration into final applications, from hardware and firmware design to software development and mass production of the final product.

The SOM Plus carrier system has several advantages over single boards. A development system and a ready-to-use board support package are included, as well as the operating system (Linux, Windows, CE, or Android) (BSP; comprising a compiler toolchain and sources). The creation of the customer’s carrier board typically includes bespoke connections, one 5V power-supply stage, and a few more components.

Due to the connection of BGA and regulated impedance connections to the memory, the PCB cost is already incorporated in the modest size of the module PCB. The mechanical requirements of the finished device are usually met by a simple, customised two-layer PCB. Users can easily switch from one platform to another by swapping modules on the same carrier board because all Engicam modules are pin-to-pin compatible.

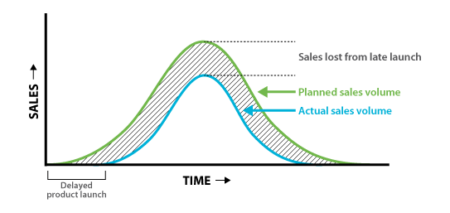

With this strategy, a variety of commodities that meet cost and/or performance criteria can be developed in a reasonably short time to market.

Engicam’s goal is to develop a large family of SOMs that may be used in a wide range of applications, including automotive, rail, and industrial/commercial. To attain this broad-use goal, each step of product design must consider the following factors: Component durability, component lifetime, component robustness, and cost are all tunable between commercial (0°C to +70°C) and industrial (–40°C to +85°C) temperature ranges.

These criteria are used to carefully select components, resulting in a versatile, scalable family of products with easy mounting options and no PCB and/or software differences between the commercial (lower-cost) and automotive (higher-cost) versions.

Engicam designed the carrier board and plastic cover for this automobile dashboard based on client specifications. In this case, the programme was created without the use of an operating system. The dashboard has been in full production for a year and is currently installed on the Bollore car-sharing group’s Pininfarina BLUECA vehicle in Paris. Micron and Silica have collaborated to provide Engicam with complete components and support solutions.

Engicam can reduce time-to-market and meet client demands thanks to Micron memory devices’ dependable high performance and lifespan, as well as Silica’s committed support, technical experience, and extensive distribution network.

Follow and connect with us on Facebook, LinkedIn & Twitter