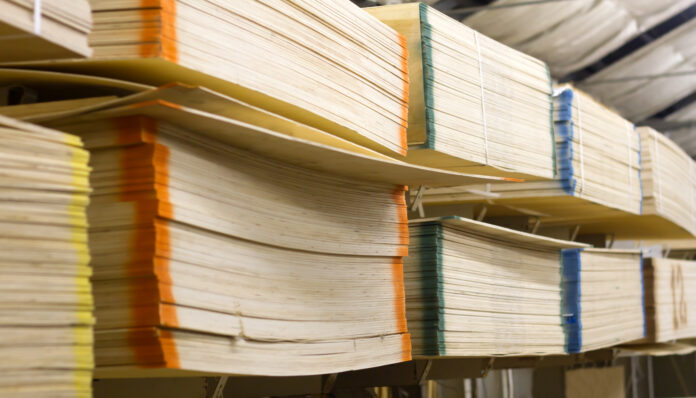

At its Joka facility in West Bengal, Century Plyboards (India) Ltd., India’s largest maker of wood panel and ornamental industries, today opened a 35000 sq. ft.

Central Distribution Centre (CDC) with a stocking capacity of 4,00,000 (four lakhs) sheets of Laminates & Veneers. With a revision of the racking system, the stocking capacity can be raised by 50%.

The entire replenishment time is predicted to be cut in half with the start of CDC operations. The service level at Regional Distribution Centers will be maintained above 95% due to faster stock restocking.

One of the most significant benefits of this CDC facility is the sophisticated Warehouse Management System, which allows all stocks to be identified and tracked with a single click. The new CDC will stock around 1000 finished goods SKUs.This project will result in a structural change in CenturyPly’s supply chain distribution model, as well as a faster rate of service fulfillment.

This supply re-networking will save the company $1 million per year in operational costs. The CDC will aid in the visibility of goods across the whole supply chain network. Due to planned and sophisticated lot sizing, it will increase production efficiency and reduce waste.

As a result, this project will radically transform the organization and propel it to a new level of sustainable development.

“The mission statement of CenturyPly has always been to be the best of all,” said Keshav Bhajanka, Executive Director of CenturyPly, “and aligning with this goal, we have further taken by establishing India’s single largest laminate distribution center, we have taken a huge step toward boosting customer satisfaction.”

“The CDC, which will be constructed in our Joka manufacturing plant in Kolkata, will feature state-of-the-art infrastructure and will be powered by one of the most technologically advanced supply chain algorithms, a pioneering movement in our business,” says the company.

“Our goal is to get as many people to see our stuff as possible at the correct time.” We’ll do it by moving the business module from order-driven manufacturing to stock-driven manufacturing, which will substantially improve our clients’ experience.

“Our goal is to give high-quality service in a shorter length of time to our consumers who have proven constant faith in our service over time,” Bhajanka added.

Follow and connect with us on Facebook, LinkedIn & Twitter